EOS Additive Manufacturing is the solution for individualised serial production of high-end, weight-optimised components in automotive engineering

Nowadays the automotive industry is focused on energy-efficient engines, reducing CO2 emissions and an increasing demand for customer-specific components in serial production. Very often it is not possible to apply them profitably to small batch sizes or where enhanced customization is required. Automobile components adapted to customer-specific requirements reflect changing customer expectations: after all an automobile conveys emotions, and the more these can be geared towards the owner, the more powerful the emotional bond. Additive Manufacturing is the solution here: it enables cost-efficient manufacture of individualized mass products.

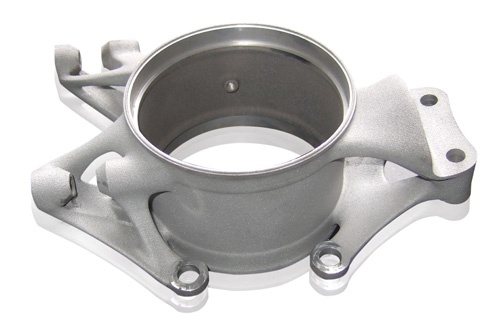

Another disadvantage of conventional manufacturing techniques is that they limit design freedom. As a result, components are always a compromise between function and feasibility. EOS Additive Manufacturing technology frees up development from these constraints, it only applies material where it is functionally necessary. This makes for extremely light and yet highly rigid parts which can even comprise integrated functions. Simple parts such as hinges, brackets and pneumatic actuators can be designed, produced and installed as integrated components. Reducing the mass of moving and/or accelerating components is especially important since this directly enhances energy efficiency.

Formula Student Germany – EOS supports racing team by producing a topology-optimized steering stub axle