DCT Metal Additive Manufacturing R&D Center By combining NCSIST’s research prowess along with Digital-Can’s marketing experience and production capability, the newly established MAM R&D Center has its sight set on building various aerospace components, and streamlines the process…

Stainless Steel exclusive M290 has joined the DCT team to provide our customers with a diverse product line.

We first began to apply for ISO certification in March of 2016, and received our AS9100 & ISO9001 certification on February 16th, 2018. This allows DCT to become the first certified metal additive manufacturing supplier in…

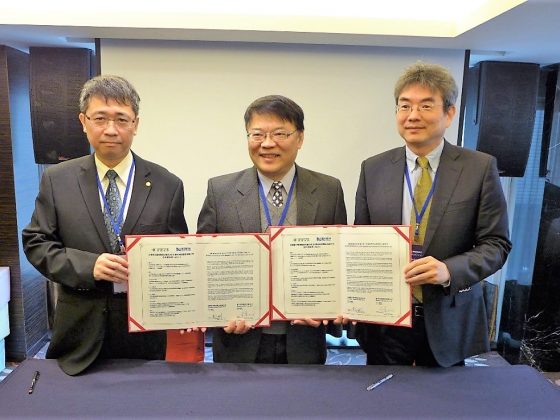

DCT forms a strategic alliance with EGAP to establish 3D Printing Central in Aerospace parts production Recently, under the supervision of Taiwan Aerospace AM (3D Printing) Commissioner, a Memorandum of Understanding was struck between DCT and EGAP…

2017.9.6-2017.9.9 Aerospace Metal Additive Manufacturing Components Exhibition DCT and NCSIST displayed their joint effort in aerospace AM components at Nangang Exhibition Hall, during which many of the high ranking officials as well as industry leaders stopped…

EOS industrial 3D printing enables cost-effective production of functional engine parts with complex geometries and defined characteristics – even in small production runs. The benefits of Additive Manufacturing (AM / industrial 3D printing) come to the…

EOS Additive Manufacturing enables aerospace companies to produce tailor-made, high-quality parts for cabin and cockpit equipment. EOS Additive Manufacturing (AM) solutions create new possibilities for aerospace companies producing cabin and cockpit equipment. Functional lightweight components such…

Additive Manufacturing by EOS enables maximum design freedom and is an ideal production method for Rapid Prototyping and small production runs Cost-effective production of prototypes and small production runs play an important role in the fast-growing…