Aluminium (AlSi10Mg)

- Good strength, hardness and dynamic properties.

- Excellent mechanical properties.

- Heat treated to improve the mechanical properties.

Design Specifications

Standard print area:

250mm x 250mm x 325mm

Min. wall / column thickness:

approx. 0.3 – 0.4mm

Technical Specifications

Material Composition:

Al (balance)

Si (≤ 9.0 – 11.0 wt-%), Fe (≤ 0.55 wt-%), Cu (≤ 0.05 wt-%), Mn (≤ 0.45 wt-%), Mg (≤ 0.2 – 0.45 wt-%), Ni (≤ 0.05 wt-%), Zn (≤ 0.10 wt-%), Pb (≤ 0.05 wt-%), Sn (≤ 0.05 wt-%), Ti (≤ 0.15 wt-%)

Relative density :

approx. 99.85 %

Density :

2.67 g/cm³

0.096 lb/in³

Copper Cu

- High purity copper.

- Good electrical and heat conductivity.

- Typical applications:heat exchagers, electronics, and variety of industry applications requiring good conductivity.

Design Specifications

Standard print area:

250mm x 250mm x 325mm

Technical Specifications

Material Composition:

Commercially pure copper (> 99.6% purity)

Relative density :

approx. >95 %

Density :

8.93 g/cm³

Conductivity as manufactured :

> 80 % IACS

Conductivity heat treated :

> 90 % IACS

Copper CuCP

- Commercially pure copper (> 99.95% purity).

- Excellent electrical and heat conductivity.

- Typical applications:electrical motors, inductors, and variety of industry applications requiring excellent conductivity properties.

Design Specifications

Standard print area:

250mm x 250mm x 325mm

Technical Specifications

Material Composition:

Commercially pure copper (> 99.95% purity)

Relative density :

approx. >95 %

Density :

8.8 g/cm³

Conductivity as manufactured :

up to 100 % IACS

Conductivity heat treated :

up to 100 % IACS

CopperAlloy CuCrZr

- High productivity 12 mm³/s with 80 µm layer thickness.

- Moderate to high conductivity in heat treated condition together with good mechanical properties.

- Typical applications:rocket engine parts, heat exchangers, and induction coils.

Design Specifications

Standard print area:

250mm x 250mm x 325mm

Technical Specifications

Material Composition:

Cr (0.5-1.2 wt-%)、Cu (98.12-99.27 wt-%)、Si (0-0.1 wt-%)、Fe (0-0.08 wt-%)、Zr (0.03-0.3 wt-%)、other (0.2 wt-%)

Relative density :

approx. >95 %

Density :

8.9 g/cm³

Conductivity as manufactured :

> 20 % IACS

Conductivity heat treated :

> 85 % IACS

Stainless Steel 17-4PH

- Precipitation hardening steels are widely used in engineering applications, which require corrosion resistance and strength.

- Stainless Steel 17-4PH can be machined, shot-peened and polished in as-built or heat treated states.

- Solution annealing together with ageing treatment are necessary in order to achieve proper hardness and mechanical properties (ASTM A564-13). Due to the layerwise building method, the parts have a certain anisotropy which can be eased by solution annealing.

Design Specifications

Standard print area:

250mm x 250mm x 325mm

Min. wall / column thickness:

approx. 0.3 – 0.4mm

Technical Specifications

Material Composition:

steel including alloying elements:Cr (15 – 17.5 wt-%), Ni (3 – 5 wt-%), Cu (3 – 5 wt-%), Si (max. 1 wt-%), Mn (max. 1 wt-%), C (max. 0.07 wt-%), P (max. 0.04 wt-%), S (max. 0.03 wt-%), Nb+Ta (0.15 – 0.45 wt-%)

Relative density :

approx. 100%

Density :

7.77 g/cm³

0.280 lb/in³

Stainless Steel 316L

- High ductility and toughness.

- The chemical composition of EOS StainlessSteel 316L corresponds to ASTM F138 material standard for Surgical Implants (UNS S31673).

- Typical applications : chermical industry, food processing and medical devices.

Design Specifications

Standard print area:

250mm x 250mm x 325mm

Min. wall / column thickness:

approx. 0.3 – 0.4mm

Technical Specifications

Material Composition:

Fe (Balance), Cr (17 – 19 wt-%), Ni (13 – 15 wt-%), Mo (2.25 – 3 wt-%), C (max. 0.03 wt-%), N (max. 0.1 wt-%)

Relative density :

approx. 100%

Density :

7.9 g/cm3

0.285 lb/in

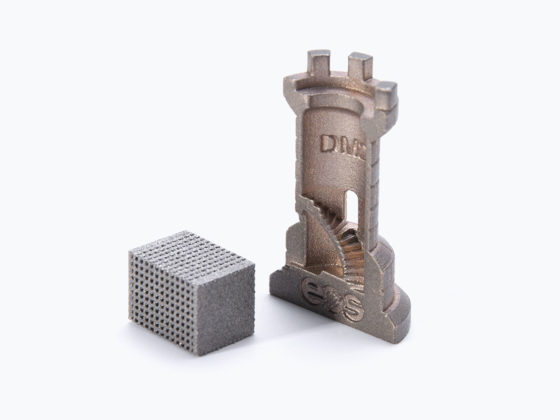

Maraging Steel

- Very good mechanical properties.

- Easily heat-treatable to obtain excellent hardness and strength.

- Certain anisotropy but can be reduced / removed with proper heat treatment.

Design Specifications

Standard print area:

250mm x 250mm x 325mm

Min. wall / column thickness:

approx. 0.3 – 0.4mm

Technical Specifications

Material Composition:

Fe (balance), Ni (17 – 19 wt-%), Co (8.5 – 9.5 wt-%), Mo (4.5 – 5.2 wt-%), Ti (0.6 – 0.8 wt-%), Al (0.05 – 0.15 wt-%), Cr & Cu (each – 0.5 wt-%), C (0.03 wt-%), Mn & Si (each – 0.1 wt-%), P & S (each – 0.01 wt-%)

Relative density :

approx. 100%

Density :

8.0 – 8.1 g/cm³

0.289 – 0.293 lb/in³

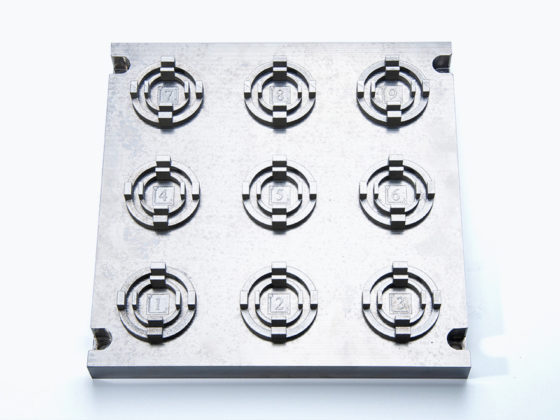

Materials Specific Facilities

Titanium TiCP Grade 2

- EOS Titanium TiCP grade 2 is commercially pure titanium alloy intended for processing on EOS DMLS™ machines.

- The parts built with EOS Titanium TiCP grade 2 powder have chemical composition corresponding to ASTM F67.

- The parts have good strength-to-weight ratio, corrosion resistance and ductility.

- Parts built with EOS Titanium TiCP grade 2 powder can be machined, shot-peened and polished in as-built and heat treated states.

Design Specifications

Standard print area:

Ø 100 x 95mm

Min. wall / column thickness:

approx. 0.3 – 0.4mm

Technical Specifications

Material Composition:

N (0.03 wt-%), C (0.08 wt-%), H (0.015 wt-%), Fe (0.3 wt-%), O (0.25 wt-%), Ti (balance)

Ultimate tensile strength:

as built:660 MPa

heat treated:570 MPa

Density:

min. 4.5 g/cm³

Titanium Ti64 ELI

- Light alloy powder.

- Excellent mechanical properties.

- Corrosion resistance with low specific weight & biocompatibility.

- Certain anisotropy but can be reduced/removed with proper heat treatment.

Design Specifications

Standard print area:

250mm x 250mm x 325mm

Min. wall / column thickness:

approx. 0.3 – 0.4mm

Technical Specifications

Material Composition:

Fe (balance), Ni (17 – 19 wt-%), Co (8.5 – 9.5 wt-%), Mo (4.5 – 5.2 wt-%), Ti (0.6 – 0.8 wt-%), Al (0.05 – 0.15 wt-%), Cr & Cu (each – 0.5 wt-%), C (0.03 wt-%), Mn & Si (each – 0.1 wt-%), P & S (each – 0.01 wt-%)

Relative density:

approx. 100%

Density:

4.41 g/cm³

0.159 lb/in³

Materials Specific Facilities

Inconel (IN718)

- Good tensile, fatigue, creep & rupture strength at temperatures up to 700°C.

- Ideal for many high-performance engineering (ex:biomedical implant, aerospace & motor racing).

- Certain anisotropy but can be reduced / removed with proper heat treatment.

Design Specifications

Standard print area:

250mm x 250mm x 325mm

Min. wall / column thickness:

approx. 0.3 – 0.4mm

Technical Specifications

Material Composition:

Ni (50 – 55 wt-%), Cr (17.0 – 21.0 wt-%), Nb (4.75 – 5.5 wt-%), Mo (2.8 – 3.3 wt-%), Ti (0.65 – 1.15 wt-%), Al (0.20 – 0.80 wt-%), Co (< 1.0 wt-%), Cu (< 0.3 wt-%), C (< 0.08 wt-%), Si & Mn (each < 0.35 wt-%), P & S (each < 0.015 wt-%), B (< 0.006 wt-%), Fe (balance)

Relative density:

approx. 100%

Density:

min. 8.15 g/cm³

min. 0.294 lb/in³

Materials Specific Facilities