Leading-edge system for the Additive Manufacturing of metal products directly from CAD data

As a leading-edge system for Additive Manufacturing, EOSINT M280 is the perfect solution for direct, cost-efficient manufacturing of high-quality metal tool inserts, prototypes and end products. Its high level of productivity and ergonomic periphery make the system ideal for the economical and batch-size optimised additive manufacturing of components throughout all phases of the product lifecycle.

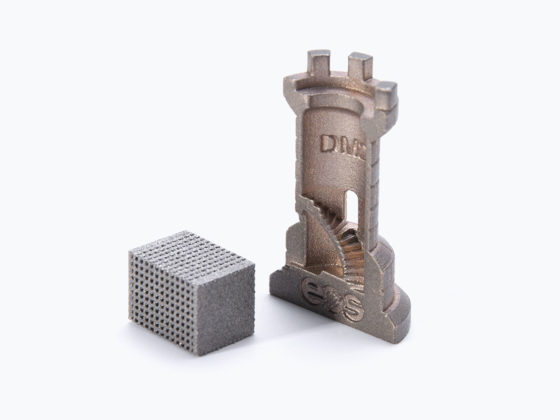

EOSINT M280 is based on the innovative DMLS (Direct Metal Laser Sintering) system by EOS. It produces components by means of Additive Manufacturing – fully automatically, without tools and based directly on three-dimensional CAD design data. For this purpose it is equipped with a 200W or 400W fibre laser which melts fine metal powder and builds up the product layer by layer. Constant monitoring of the process ensures that all components are produced in excellent, reproducible quality. This method allows you to create products with extremely complex geometries including elements such as free-form surfaces, deep slots and coolant ducts.

Innovation

- Additive Manufacturing of products from CAD data by means of Direct Metal Laser Sintering (DMLS)

- For each material you can choose between optimised surface and productivity using the EOS parameter sets

Quality

- High level of beam quality and performance stability with a 200W or 400W fibre laser

- Monitoring of all levels during the construction process based on EOSTATE reports

- High quality achieved in all components

Flexibility

- Simple integration in existing production environments

- A wide range of materials can be processed – from light alloys through to high-grade steels, tool steels and superalloys

- Modular, upgradable solutions, for example with IPCM-M or M 280 Comfort Power Module

User-friendliness

- Low-dust, ergonomic working conditions

- Minimum requirements in terms of set-up conditions

- Data can be processed conveniently at the workplace

Innovation

- Additive Manufacturing of products from CAD data by means of Direct Metal Laser Sintering (DMLS)

- For each material you can choose between optimised surface and productivity using the EOS parameter sets

Quality

- High level of beam quality and performance stability with a 200 W or 400 W fibre laser

- Monitoring of all levels during the construction process based on EOSTATE reports

- High quality achieved in all components

Flexibility

- Simple integration in existing production environments

- A wide range of materials can be processed – from light alloys through to high-grade steels, tool steels and superalloys

- Modular, upgradable solutions, for example with IPCM-M or M 280 Comfort Power Module

User-friendliness

- Low-dust, ergonomic working conditions

- Minimum requirements in terms of set-up conditions

- Data can be processed conveniently at the workplace

Technical Data

EOS M 280 Building volume 250 mm x 250 mm x 325 mm (9.85 in x 9.85 in x 12.8 in) Laser type Yb-fibre laser, 200 W or 400 W (optional) Precision optics F-theta-lens, high-speed scanner Scan speed up to 7.0 m/s (23 ft/s) Focus diameter 100 μm - 500 μm (0.004 in - 0.02 in) Power supply 32 A Power consumption maximum 8.5 kW / typically 3.2 kW Nitrogen generator integrated Compressed air supply 7 000 hPa; 20 m³/h (102 psi; 706 ft³/h) Dimensions (B x D x H) System 2 200 mm x 1 070 mm x 2 290 mm (86.6 in x 42.1 in x 90.1 in) Recommended installation space minimum 4.8 m x 3.6 m x 2.9 m (189 in x 142 in x 114 in) Weight approx. 1 250 kg ( 2.756 lb) Data preparation Software EOS RP Tools; EOSTATE Magics RP (Materialise) CAD interface STL (optional: converter for all standard formats) Network Ethernet EOS monitoring solutions available

EOS Monitoring-Products EOS M 400 EOS M 290 EOSINT M 280 / M 270 1 EOSTATE Base ✕ ✕ ✕ EOSTATE Laser ✕ ✕ ✕ 2 EOSTATE Modul QualityAssurance ✕ ✕ ✕ EOSTATE Modul Controlling ✕ ✕ ✕ EOSTATE Modul MachinePark ✕ ✕ ✕ 3 EOSTATE PowderBed ✕ ✕ 4 EOSTATE MeltPool ✕