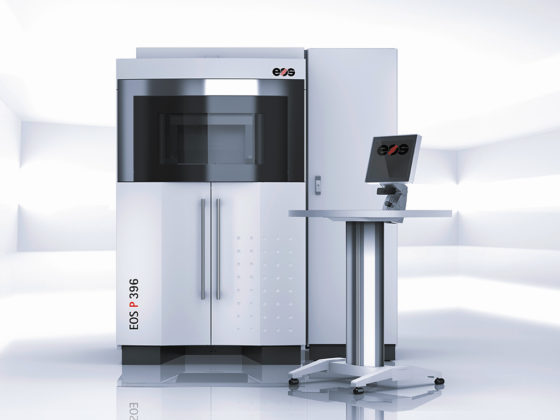

Processing Polymers at Operating Temperatures of up to 300°C

The innovative manufacturing platform produces high-quality components at the lowest cost-per-part. Thanks to clever hardware interfaces and accessories, the uptime of the EOS P500 increases by up to 75% compared to predecessor systems and competition models

Processing Polymers at Operating Temperatures of up to 300°C

Thanks to clever hardware interfaces and accessories, the uptime of the EOS P500 increases by up to 75% compared to predecessor systems and competition models.

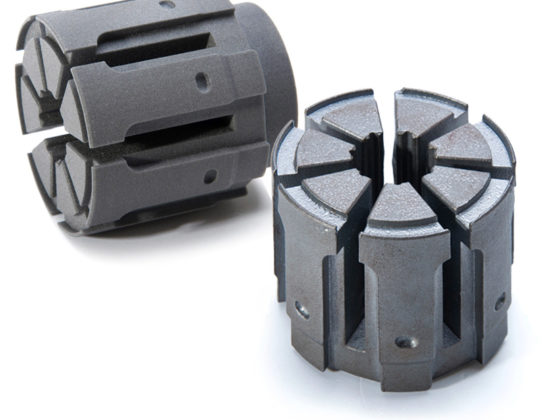

Cost-effective manufacturing

- The innovative recoater, which applies and densifies material with a speed of up to 0.6m/sec, as well as two powerful 70 watt lasers reduce cost-per-part by more than 30%.

The new 3-stage filter unit

- The new 3-stage filter unit and an intelligent thermo- and protective gas management ensure optimum process conditions.

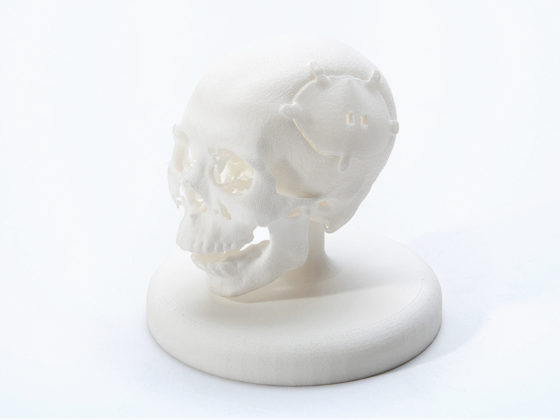

High productivity

- The system processes polymer materials at operating temperatures of up to 300°C enabeling maximum material flexibility. Open software interfaces and user-friendly tools support application and material development.

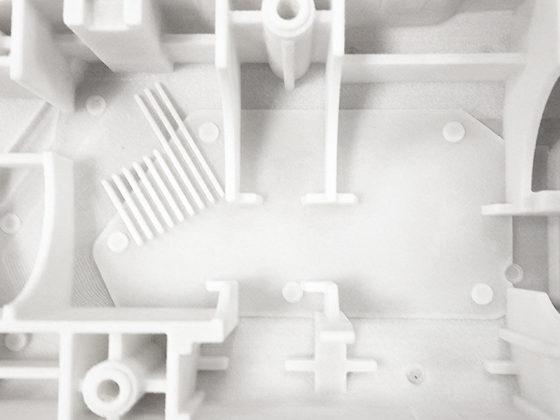

Innovative software

- SmartScaling compensates shrinkage behaviour contributing to perfect dimensional accuracy.

- With EOSYSTEM the machine is operated intuitively. EOSPRINT 2 enables software integration in CAD systems, e. g. NX™ from Siemens and via EOSCONNECT the connection to ERP systems. Thus the EOS P500 supports a digital control of production.

User-friendly

- Extensive sensor technology plus optical and thermal monitoring enable excellent process monitoring to meet the requirements of the aerospace and automotive industries.

Automated interfaces

- Automated interfaces and optimized accessories reduce the cycle time drastically and ensure building process of several days duration.

Technical Data

EOS P 500 Building volume 500 x 330 x 400 mm Building speed (depending on material) up to 40 mm/h;up to 6.6 l/h Layer thickness (depending on material) 0.06 mm (0.00236 in), 0.10 mm (0.00394 in), 0.12 mm (0.00472 in), 0.15 mm (0.00591 in), 0.18 mm (0.00709 in) Laser type CO₂, 2X70 W Precision optics F-theta lens, surface module, high-speed scanner Scan speed during building up to 2 x 10 m/sec Power supply 400 V/100 A; max. power consumption 80 A Compressed air supply nominal 10 kW, typical 2.4 kW Dimensions (W x D x H) Dimensions (W x D x H) 3400 x 2100 x 2100 mm Recommended installation space 7.2 x 5.2 x 4.2 m Weight approx. 7,000 kg (15,432 lb) Data preparation Software EOS PSW, EOS RP Tools, EOSTATE CAD interface STL Network Ethernet Certification CE, NFPA