EOS Additive Manufacturing can also be used to repair damaged tool inserts, saving manufacturers time and money.

The repair of damaged tool components is an application area in which innovative Additive Manufacturing technology from EOS can really demonstrate its strengths.

Instead of having to dispose of a worn-out tool and replacing it with a new one, the damaged areas can be repaired quickly using laser sintering. This enables manufacturers to benefit from a longer operating life, also reducing operating costs.

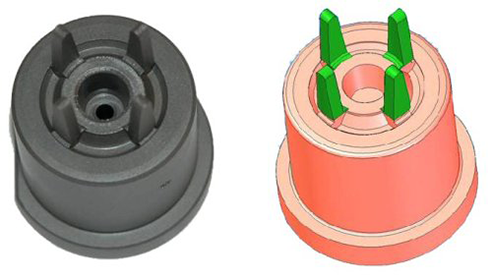

Repair instead of replacement…

Here is an example to show what can be achieved: Ecoparts AG in Rüti, Switzerland uses DMLS technology from EOS to provide services to customers from a wide variety of industrial areas. These include rapid manufacturing, rapid tooling and solution engineering for injection moulding.

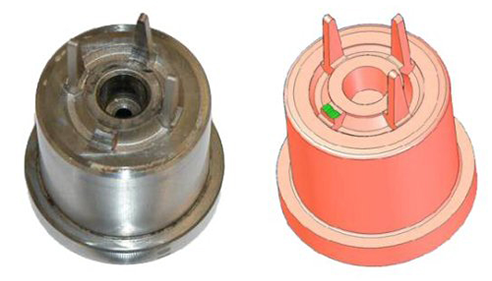

One of the solutions on offer is the repair of partly defective tool inserts. Ecoparts first produces a new reference surface through grinding and sharpening. The EOSINT M 270 laser sintering system is then used to build up the missing structures layer-by-layer on the prepared pre-form using the CAD construction data. This means that users do not need to rebuild the components from scratch. This saves them time and money.