Key New Features of PrintRite3D 7.0

- Temperature Monitoring and Calibration:

Now includes a cooling rate enabling classification of crystalline structures and Celsius and Kelvin conversion.

- Recoater Interaction Detection:

Provides greater diagnostic accuracy and faster than visual methods.

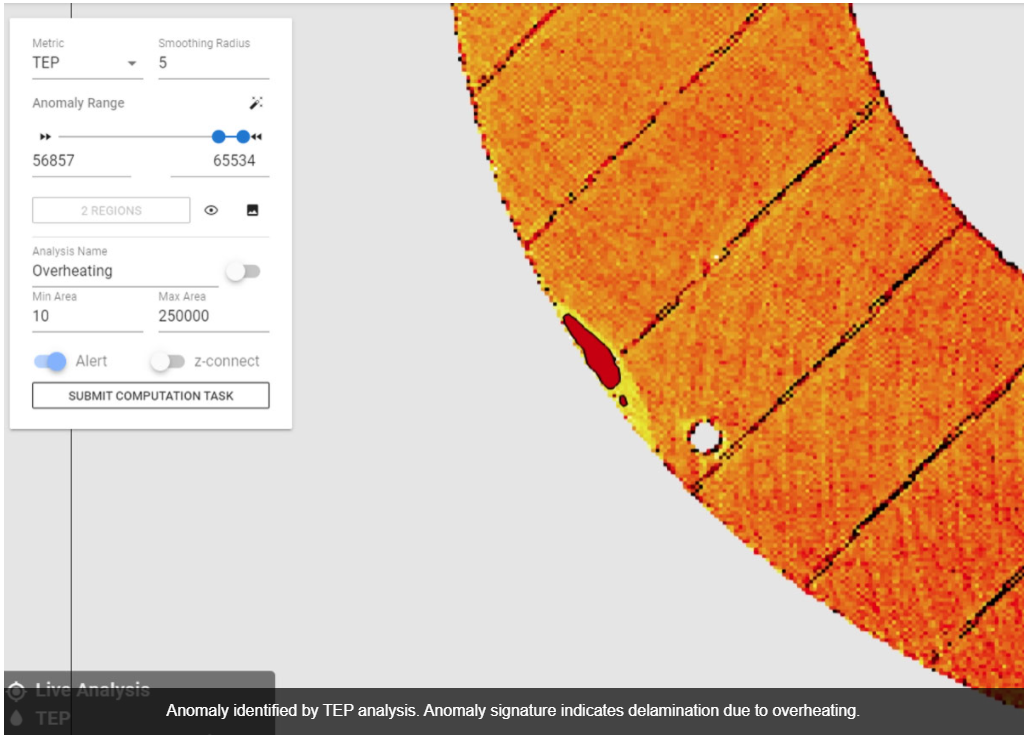

- Machine Learning:

Customizes the detection toolkit by defining anomaly signatures that are unique to user machines, parts and builds scenarios. Alert operators when an occurrence frequency exceeds established thresholds.

- Predictive Modeling:

import ‘as-built’ conditions into analysis software to determine the effects of anomalies on part performance; a key step in establishing a “digital twin”.

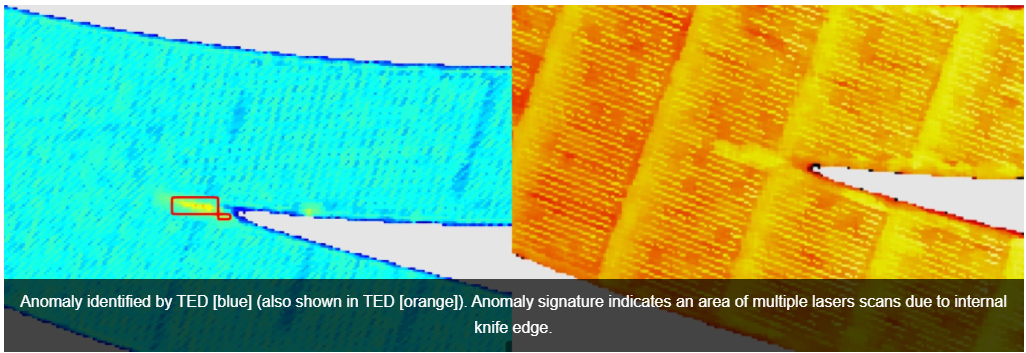

- Multi-Laser:

Gain confidence in large builds by verifying weld integrity and metal quality in areas where lasers interact.

- User Roles and Log In:

Control access to sensitive data and maintain traceability of actions for regulatory compliance.

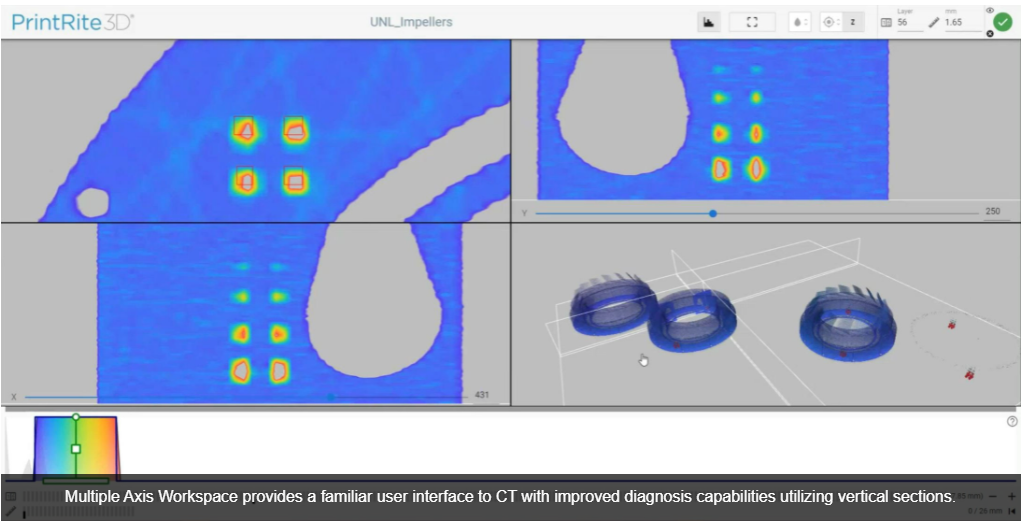

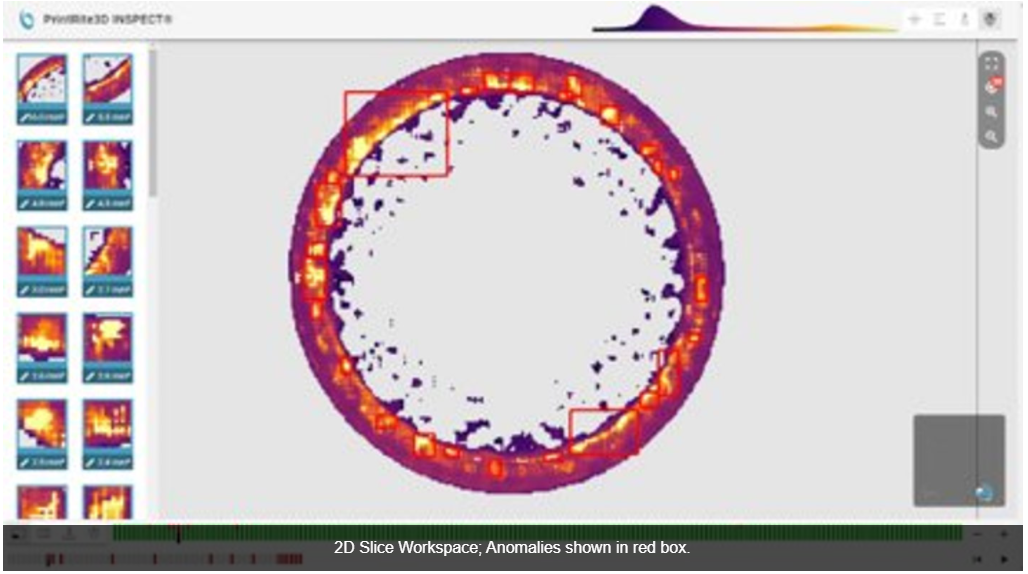

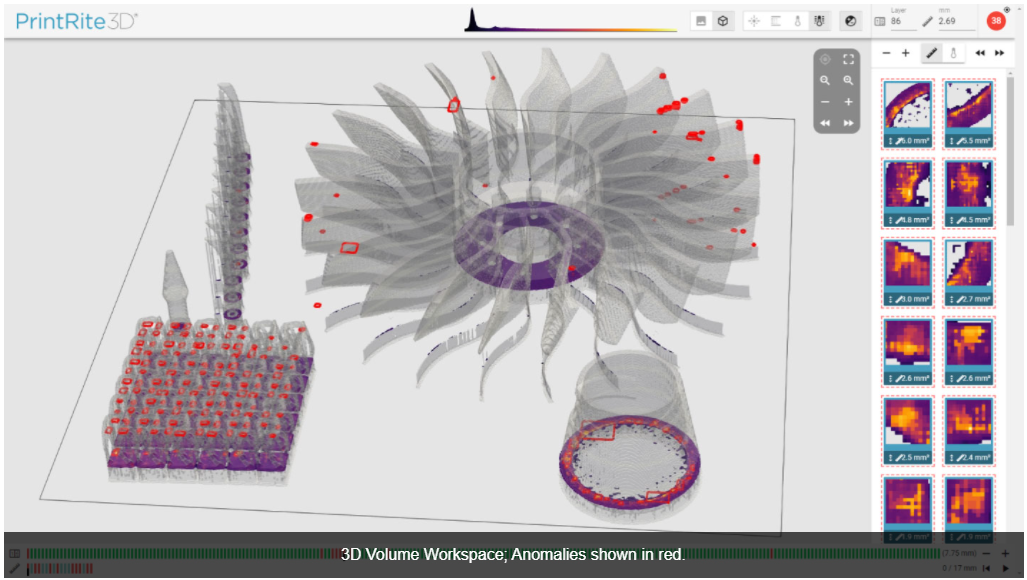

- Multiple Viewing Modes:

Statistical charts, 2D Layers, 3D Volume, and now introducing Multi-Axis view enabling XYZ views for advanced analysis of vertical x-sections.

Benefits of PrintRite3D 7.0

Actionable knowledge of what is occurring inside your machine during the build process:

- Catch show-stopping anomalies early

- Make fixes-on-the-fly – adjust process parameters to correct errors

- Terminate unrecoverable builds to conserve consumables and machine time

- Observe status and quality of all builds running on the production floor

Increased productivity with:

- Higher throughput

- Better OEE

- Improved process consistency

- Optimization of AM processes to balance productivity with part quality

A significant step toward the promises of Industry 4.0:

- Machine learning

- Predictive modeling

- Automation leading to less reliance on man-in-loop

Reduce risk of part failure:

- Build quality by design (QBD) into your parts and processes

- Gain trust in your AM technology

- Measure quality with proven industry standards

Save costs and time on your parts and production runs:

- Fewer pre-production trials

- Eliminate time and money spent on corrective post processes

- Monitoring real-time reduces reliance on CT