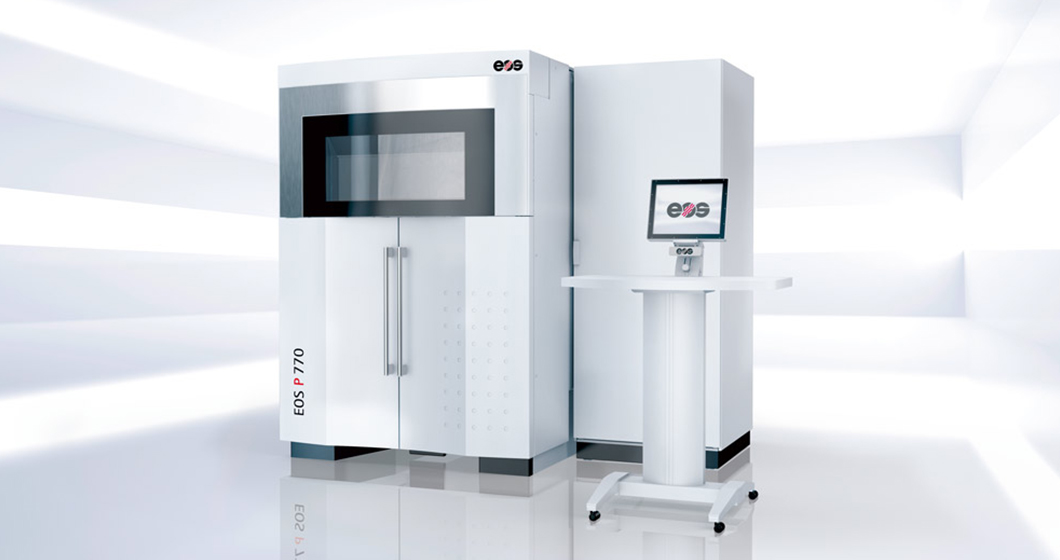

High productive Laser Sintering System for parts of up to one meter in length

Improved part quality with a build volume of over 150 liters

The EOS P770 is a Laser Sintering System with two lasers for the production of large parts and for industrial high-throughput manufacturing. The system has the largest building volume available on the market. Thanks to its new hardware and software features, the EOS P770 is up to 20 percent more productive than its predecessor.

With 10 commercial polymer materials and 18 combinations of materials / layer thicknesses currently available for the EOS P770, EOS is a benchmark in terms of material variety.

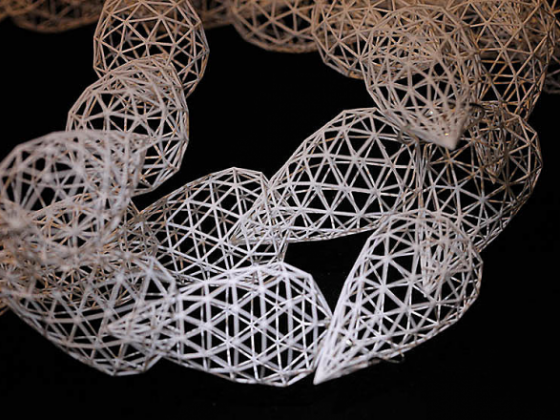

Shapeways – Kinematics Dress by Nervous System 3D Printed on EOS P760 SLS. Systems similar to EOS P770

High productive Laser Sintering System for parts of up to one meter in length

Improved part quality with a build volume of over 150 liters

The EOS P770 is a Laser Sintering System with two lasers for the production of large parts and for industrial high-throughput manufacturing. The system has the largest building volume available on the market. Thanks to its new hardware and software features, the EOS P770 is up to 20 percent more productive than its predecessor.

With 10 commercial polymer materials and 18 combinations of materials / layer thicknesses currently available for the EOS P770, EOS is a benchmark in terms of material variety.

Shapeways – Kinematics Dress by Nervous System 3D Printed on EOS P760 SLS. Systems similar to EOS P770

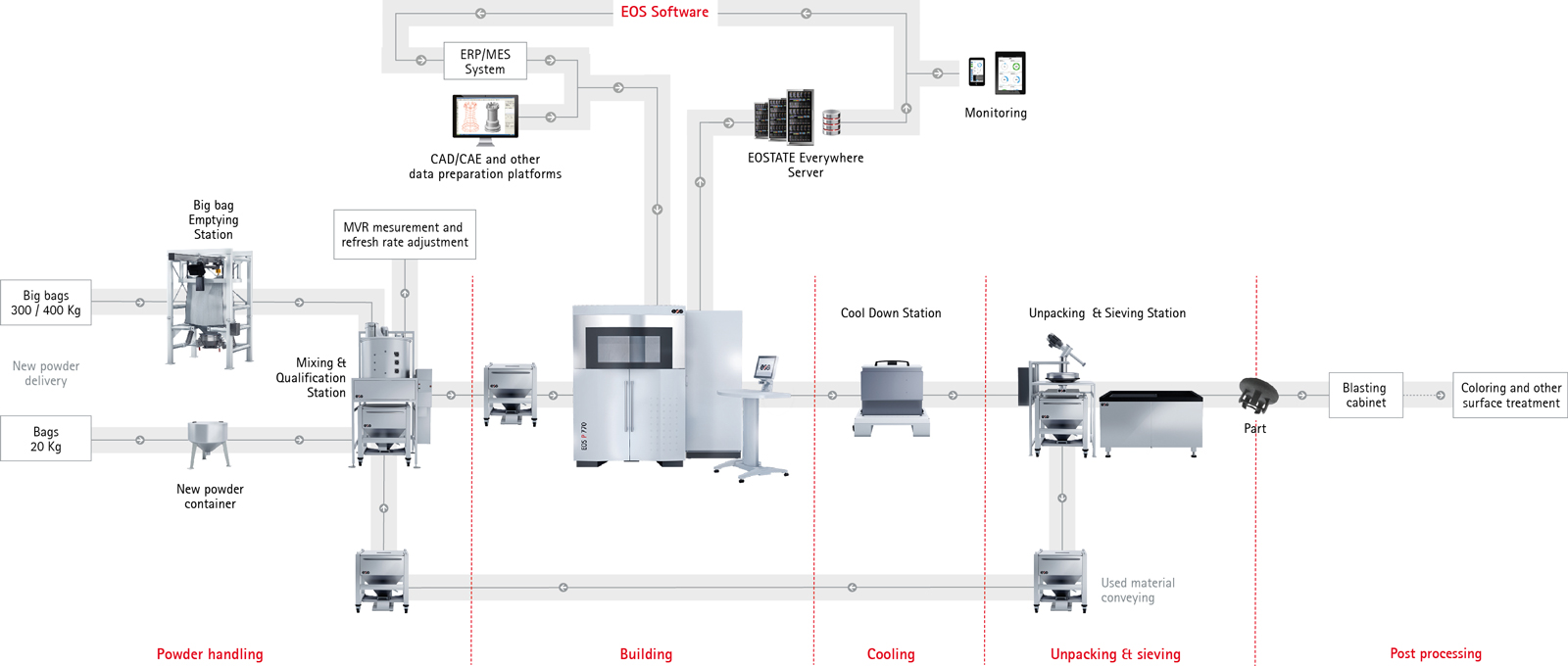

Efficiency

- Optimized temperature management, improved recoating speed and high-power lasers reduces the build time and cost per part significantly

- Well-established EOSAME feature homogenizes the energy input, thus ensuring excellent mechanical part properties and dimensional accuracy within the overall build volume*

* the specified build volume depends on the material; for PA2200 it is 700 x 380 x 580mm (27.6 x 15 x 22.9 in)

Quality

- Improved digital scanners for considerably higher laser accuracy. As a result the overlap area has no visible edges

- Integrated CoolDown Station provides optimal cool down conditions which lead to the best properties in the final part – in particular with regard to dimensional accuracy and colour stability.

- Continuous and accurate temperature control enabled by the spot pyrometer

Flexibility

- 10 commercial polymer materials and 18 combinations of materials / layer thicknesses are available

- EOS ParameterEditor allows definition of customized exposure parameters based on proven starting values

Technical Data

EOS P 770 Effective building volume 700 mm x 380 mm x 580 mm (27.6 x 15 x 22.9 in) Build rate up to 32 mm/h** (1.3 in/h); up to 10.5 l/h Layer thickness (depending on material) 0.06 mm (0.00236 in), 0.10 mm (0.00394 in), 0.12 mm (0.00472 in), 0.15 mm (0.00591 in), 0.18 mm (0.00709 in) Laser type CO₂, 2 x 70 W Precision optics F-theta lens, surface module, high-speed scanner Scan speed during build processs up to 2 x 10 m/s (32.8 ft/sec) Power supply 32 A Power consumption typical 3.1 kW; maximum 12 kW Dimensions (B x T x H) System 2,250 mm x 1,550 mm x 2,100 mm (88.6 x 61 x 82.7 in) Recommended installation space min. 4.8 m x 4.8 m x 3.0 m (189 x 189 x 118 in) Weight approx. 2,300 kg (5,071 lb) Software EOS ParameterEditor, EOSAME, EOS RP Tools, EOSTATE Everywhere, PSW 3.8 Materials* Alumide, PA 1101, PA 1102 black, PA 2200, PA 2201, PA 3200 GF, PrimeCast 101, PrimePart FR (PA 2241 FR), PrimePart PLUS (PA 2221) Optional accessories CoolDown Station, IPCM P, IPCM P plus, unpacking and sieving station, blasting cabinet ** typical build rate for PA 2200 for 120 μm (0.00472 in) layer thickness