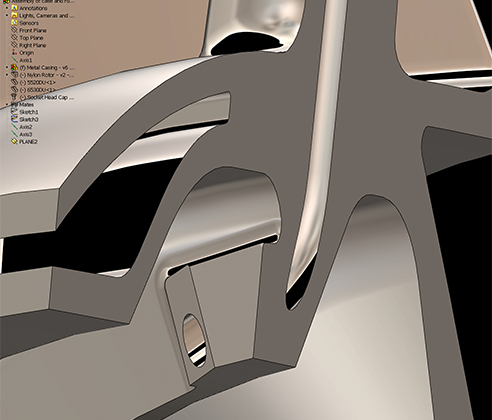

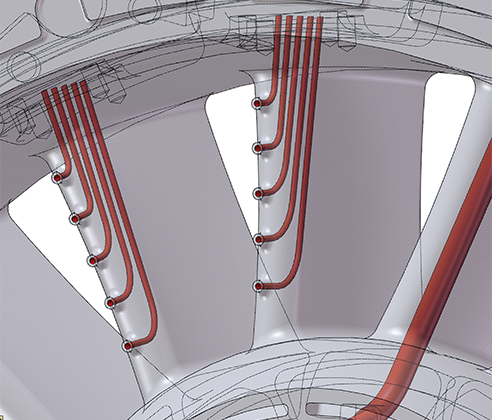

EOS industrial 3D printing enables cost-effective production of functional engine parts with complex geometries and defined characteristics – even in small production runs.

The benefits of Additive Manufacturing (AM / industrial 3D printing) come to the fore in the production of engine and turbine parts, even for small batch sizes. Functional parts with demanding geometries and defined aerodynamic or fluid-dynamics properties can be manufactured quickly and cost-effectively using EOS laser sintering equipment. That includes fuel systems, guide vanes and turbine blades, add-on systems and special heat protection components. Even extremely complex components made from high-strength material, which may contain cavities or oil lines, can easily be produced using AM from EOS, while the use of conventional manufacturing processes for such parts is either impossible or very expensive.