Additive Manufacturing by EOS enables maximum design freedom and is an ideal production method for Rapid Prototyping and small production runs

From Design Sketch to First Flight in One Month

Another benefit of AM is the quick availability of products: Southampton University developed and manufactured the “SULSA” UAV in less than one month. Production was based on EOS AM technology and completed within just one week by 3T RPD Ltd. The entire body including the wings and tail consists of just five components with simple snap-on connectors. In its maiden voyage, the UAV displayed excellent aerial abilities.

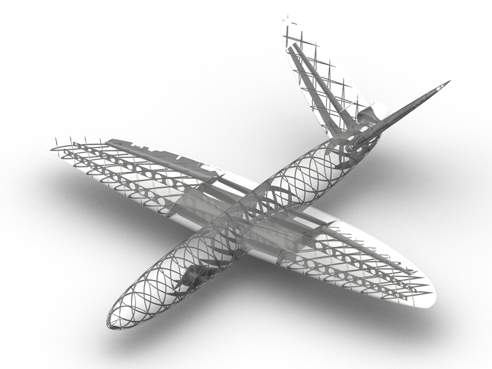

Geodetic structures to reinforce UAV design Material: PA 2200 (Source: EOS)

Internal structures of SULSA aircraft, Material: PA 2200 (Source: EOS)