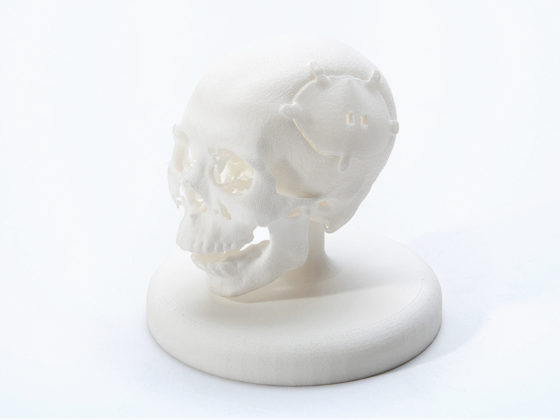

PA2200 (NYLON POLYAMIDE)

- Multipurpose material – high strength & stiffness

- Good chemical resistance & excellent constant behaviour

- Bio compatible (EN ISO 10993-1 & USP / level VI / 121°C)

- Approved for food contact in compliance with the EU Plastics Directive 2002 / 72 / EC (exception: high alcoholic foodstuff)

Design Specifications

Standard print area:

340mm x 340mm x 600mm

Min. wall / column thickness:

0.6mm

The printed object is rigid when more than 2mm thick

Min. embossed / engraved details:

0.5mm

Min. thickness for readable text:

0.5mm

Min. clearance for interlocking parts:

0.5mm

Accuracy tolerance:

Greater of ± 0.1 mm or ± 0.15%

(Note:accuracy is geometry dependent)

Technical Specifications

Tensile Strength:

48 MPa

Tensile Modulus:

1,700 Mpa

Tensile Elongation:

24%

Flexural Strength:

58 Mpa

Flexural Modulus:

1,500 Mpa

Izod Impact – Notched:

4.4 kJ/m²

Materials Specific Facilities

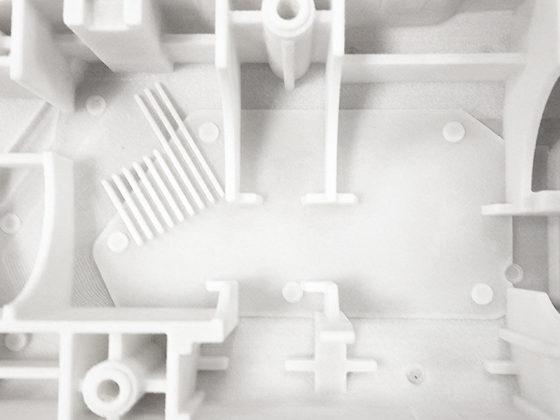

Glass Filled Fine Polyamide (PA3200 GF)

- Excellent Mechanical Properties

- Very smooth surfaces

- High accuracy

- Excellent long term constant behaviour

Design Specifications

Standard print area:

340mm x 340mm x 600mm

Technical Specifications

Tensile Strength:

48 ± 3 N/mm²

Tensile Modulus:

3200 ± 200 N/mm²

Tensile Elongation:

6 ± 3 %

Flexural Modulus:

2100 ± 150 N/mm²

Izod Impact Strength:

21.3 ± 1.7 kJ/m²

Izod Notched Impact Strength:

4.2 ± 0.3 kJ/m²

Materials Specific Facilities

PrimeCast 101

- Suitable for ceramic shell casting

- Application for production of master patterns for vacuum casting

- Dimensional accuracy

- Low melting point

Design Specifications

Standard print area:

200mm x 250mm x 330mm

Technical Specifications

Tensile Modulus:

1600 MPa

Tensile Strength:

5.5 MPa

Density:

770 g/m³

Materials Specific Facilities