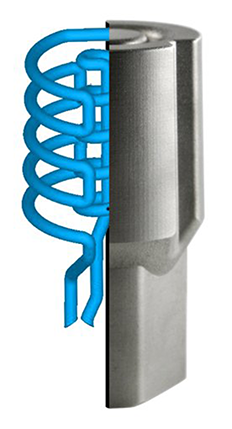

EOS Additive Manufacturing can integrate tempering channels in a tool directly and in near-contour conditions, thereby optimising heat diffusion.

One of the major challenges in die-casting is the defined cooling of the tools used during serial production. This is where conventional tool production processes reach their limits: Tempering channels can only be drilled in straight lines. This means that critical hotspots can often not be reached with coolants and thus cannot be relieved. As a consequence, the tool can become misshapen and its service life will be reduced. In addition the partly deficient heat dissipation is responsible for long cooling times for the manufactured products.

Innovative Additive Manufacturing from EOS on the basis of DMLS (Direct Metal Laser Sintering) is the answer: This makes it possible to integrate optimised tempering channels in the tool directly and under near-contour conditions during production. This means that heat can be dissipated much after and more evenly, while hotspots can be cooled on a targeted basis. Manufacturers benefit from numerous advantages: the tool retains its shape better and lasts longer. In addition, the plastic product quality and dimensional accuracy of the manufactured parts is enhanced, and drastically reducing cycle times.

Laser sintering technology example

LBC managed to design and manufacture a tool insert with significantly optimized tempering performance for a die-cast application. LBC constructed the insert from EOS MaragingSteel MS1 using the DMLS technique on an EOSINT M 270 laser sintering machine. During manufacturing, near contour tempering channels were integrated in the tool at defined points, significantly improving cooling performance. This enabled the manufacturer to reduce the cycle time by 20 %